|

|

2.3 Turbo

Frequently Asked Questions

All information given below are general guidelines. Each

car or engine is slightly different and may require additional tuning for

safe/optimal performance.

Additional FAQ topics can be viewed on our support forum here:

Support Forum FAQ

Contents

-Why can't I use

the stock ecu/mass-air meter for the turbo swap?

-Why can't I use the stock 2.3 n/a

engine for the turbo swap?

-What turbo computer should I use for optimal performance?

-What turbo should I get for

"X" hp?

-What mods do I need for

"X" hp?

-What do all those turbo specs mean?

-How much boost

can my turbo safely put out?

-How much boost

can I safely run?

-How much power will

the stock ECU handle?

-How much power will the stock 35lb injectors handle?

-How much power will the stock

vane air meter (VAM) handle?

-How much power will the stock

turbo engine handle?

-Can I convert my air meter to blow-thru?

-Can I use a n/a head on a turbo motor?

-Can I just put forged pistons in my stock 2.3 n/a engine and convert to

turbo?

-What spark plugs should I use?

-What should I gap the spark plugs to?

-What spark plug wires should I use?

-Can I use a small air meter/injectors with a computer that came with large

air meter/injectors (or visa-versa)?

-What options do I have for tuning/modifying the computer settings?

-What is a wideband oxygen sensor and why do I need one?

-What

is the purpose of a blow off valve (bov)?

-What

is the purpose of a bypass valve (bpv)?

-What

is the purpose of a wastegate?

-Should

I use an internal or external wastegate?

-Will

3" exhaust kill my low end power because it doesn't have enough

backpressure?

-What

is the best size of intercooler tubing?

-Will

too large of an intercooler or too much tubing cause excess lag?

-What

clutch do I need for "X" hp?

-Can

I use the stock Mustang fuel pump with my new turbo engine?

-What

fuel pump should I use for my modified 2.3T?

-Factory

Ford 2.3T Application Information & Sensor Descriptions

(new).

Why

can't I use the stock ecu/mass-air meter for the turbo swap?

The main reason you can't

"safely" use the stock Mustang computer and mass-air meter is

because there is nothing available to tune the stock ECU for larger

injectors, a larger air meter, timing retard under boost, etc. The stock

air meter and small stock n/a injectors wouldn't support more than about

130rwhp which isn't even worth messing with.

Why can't I use the

stock 2.3 n/a engine for the turbo swap?

In all honesty, you can. We just

wouldn't suggest it. Between the higher compression, heart shaped

combustion chambers, and cast pistons, it will be a ticking time-bomb. We

know at least a dozen people who have turbocharged the stock naturally

aspirated engine and all of them have eventually blown them up because of

a minor tuning issue or part failure. As cheap as the turbo engines are,

it's silly to do it any other way. If you drop forged and dished pistons

designed for turbo applications

into a n/a block, it will be as good as a stock turbo engine though.

What stock turbo computer

should I use for optimal performance?

Optimal performance and 30+ year old

ECU/electronics don't really belong in the same conversation. If you're

only looking to make similar power to stock (130-215hp at the wheels)

then for the most part, the computers from 87-88

Thunderbird Turbo Coupes can do an "OK" job of controlling things as long

as the matching "Big VAM" and brown top 35lb/hr low impedance injectors

are also used. The catch codes for these ECU's include the LA3, LA2, LA, 8UA, and

LB3 codes. All of them are functionally interchangeable with each

other as long as a 5 speed is used. The automatic trans ECU's work just

fine with a 5 speed, they will just throw a few codes but will not trigger

the check engine light. If running an automatic, you'll need

the 8AU or LB3 to control the transmission, unless it's a 3 speed auto

which isn't computer controlled.

The reason we prefer this ECU is because it is the last generation of 2.3T

computers and they have faster processors and tend to run smoother while

making as much or more power than any other factory ECU.

Of course for

ultimate tuneability and power potential, our PiMPx or PiMPxs ECU is ideal.

If you plan to make more than 250hp then a PiMPx or PiMPxs is

essentially mandatory as you'll need larger than stock injectors and

you'll need to get rid of the restrictive VAM, both of which can't be

done with the Ford ECU's but are done with our ECU. Our ECU options can

be viewed here:

PiMP ECU's

What turbo should I get for "X" hp?

Remember these are estimated "maxed out" power

quotes. It does not mean you'll make this much power automatically with

this turbo.

-Stock (87-88 Turbo

Coupe) Ishi-Warner IHI: Less than 250 rwhp, super quick spooling (full

boost at 1800-2300 rpm with a few airflow mods) but runs out of steam at

higher engine speeds. Great for heavy cars or daily drivers. Good to 18psi

or so.

-Stock (83-86 Mustang/Turbo Coupe, 84-89 Merkur) Garrett/AiResearch

T3: Up to about 275 rwhp. Full boost at 2500-3000 rpm or so with a few

airflow mods, pulls pretty well up top. Has a very hard "kick"

when boost kicks in. Great for a daily driver/street terror with minor

mods. Good to 23 psi or so if you've got enough fuel, octane, intercooling,

etc. to safely run that much.

-T3/T4 Hybrid T04E 46 trim compressor/Stage III exhaust side with .48 a/r for

street cars, .63 a/r for street/strip. Great for engines in the

250-350rwhp range. Full boost at 3000-3300 rpm or so with a header and

supporting mods. Nice linear power throughout rpm range. Great for

street/strip cars in the 12-13 second 1/4 mile range. Good to 25psi or so.

-T3/T4

Hybrid T04E 50 trim compressor/Stage III exhaust side with .48 a/r for

street cars, .63 a/r for street/strip: Great for engines in the

300-410 rwhp range. Full boost at 3300-3500 rpm or so with

supporting mods. Nice linear power throughout rpm range. Great for

street/strip cars in the 11-12 second 1/4 mile range. Good to 35psi or so

(if your tune and engine can handle it).

-Holset HY35:

Great for engines in the 300-450+rwhp range. Full boost at 3600-4000 rpm or so

with supporting mods. Pulls like a freight train in the

higher rpm range. Great for street/strip cars in the 10-12 second 1/4 mile

range. Loves 30+psi of boost.

-Holset HE351:

Slightly upgraded version of HY35. Great for engines in the 300-450+rwhp

range. Full boost at 3600-3800 rpm or so with supporting mods.

Pulls like a freight train in the higher rpm range. Great for street/strip

cars in the 10-12 second 1/4 mile range. Loves 30+psi of boost.

-Holset HX35:

Great for engines in the 380-450+rwhp range. Full boost at 3800-4000 rpm or so

with a header and supporting mods. Pulls like a freight train in the

higher rpm range. Great for street/strip cars in the 10-11 second 1/4 mile

range. Loves 30+psi of boost. Split scroll exhaust housing causes boost

control problems unless an external wastegate is used or the divider is

cut out.

-T61:

Great for engines in the 400-600 rwhp range. Full boost at 4000rpm or so

with a header and supporting mods. Great for serious street cars or drag

cars in the 9-10 second 1/4 mile range. Can handle upwards of 40psi.

-There

are also many new turbo from Borg Warner like the EFR series or the

S200-S300's, Garrett GT series, etc. that will exceed the performance of

the turbos listed above. I

did not include them because they are a much more expensive turbo and

since they have many more options available so it's hard to pinpoint exact

specs for your 2.3T so they should be spec'd out specifically for your

setup.

What mods do I need for "X" hp?

All combos are assumed

to be utilizing the best "stock" setup which includes 35lb

injectors, large vam, 87-88 ECU, stock or ranger roller cam (unless

stated otherwise), and

most importantly a good running engine with no issues. Common problems on

these old engines like worn slider cams, worn out valve springs, and

worn and leaking valve seats will severely limit power production.

Remember these are estimated "maxed out" power quotes. It does not mean

you'll make this much power automatically with this combo. It simply

means when everything is perfect, dialed in, and maxed out, it should

make around the power quoted. It is very beneficial to have a wideband

o2 controller setup like these (Stinger

Performance Widebands)

-Stock

engine, stock intercooler, no significant mods, 15-18psi will produce

roughly 170-215rwhp.

-Above

setup plus cone filter, 3" exhaust, 15-20psi will produce roughly

200-235rwhp.

-Above

setup plus front mount intercooler, more boost, elevated fuel

pressure, 255 lph fuel pump, ~22-23 psi will produce roughly 240-265rwhp.

-Above

setup plus ported or gutted intakes, mildly ported head, ~22-23 psi will

produce roughly 265-300rwhp IF you run significantly higher than stock

fuel pressure (you'll need a wideband o2 setup to analyze the air/fuel

ratio to find proper fuel pressure).

-Above

setup plus professionally ported head flowing 215+cfm on the intake,

extremely high fuel pressure, ~22-23 psi will produce roughly 275-315rwhp

with very high base fuel pressure (or run larger injectors, turbo, and a tuneable ECU

like our PiMP and it could be 325-375rwhp).

Below requires upgraded injectors which requires a PiMPx or PiMPxs ECU

(PiMP

ECU's)or piggyback ECU tuner, and

conversion to speed density to ditch the VAM along with race fuel, E85, or

methanol injection.

-Stock engine,

larger turbo, header, professionally ported head and intake flowing 225+cfm, cone filter,

3" exhaust, FMIC, 255 lph fuel pump, large

aftermarket cam like a Stage 2 or Stage 3 from Boport at ~25-30 psi will produce roughly 350-450rwhp (stock rods

won't last long at over 400rwhp unless the tune is perfect so plan

accordingly).

Below requires many unmentioned items plus a standalone EFI system such

as our

PiMP ECU.

-Above

mods plus Upgraded Rods/Pistons, 225+cfm iron head or Esslinger Aluminum D

port head, ~30 psi will produce roughly 400-500rwhp.

-Above

mods plus Esslinger SVO head, Stage III or larger Bo-Port cam, ~25-30 psi will

produce roughly 450-600rwhp.

-Above

mods plus Esslinger ARCA or XT head, Stage IV or larger Bo-Port cam, 2.65L+ stroker

engine, ~30-35 psi will produce roughly 700-1100rwhp.

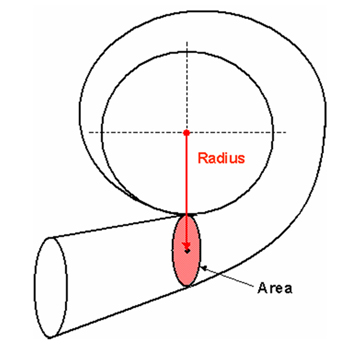

What do all those turbo specs mean?

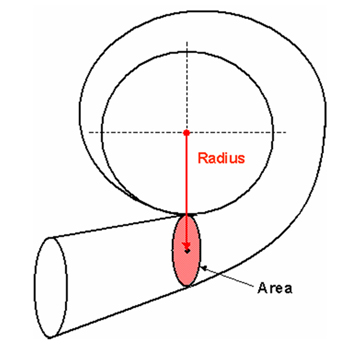

A/R is the Area to Radius

ratio...literally a measurement of the size of the exhaust housing. Picture of

a/r measurement from Garrett Turbos:

A Stage

III exhaust wheel is a larger/higher flow version of a standard

Stage I

wheel. The physical dimensions of the wheel are larger. These require a Stage

III exhaust housing that matches the shape and size of the Stage III wheel.

The

stock T3

has an

exducer diameter of

1.898" and a major

diameter of

2.319"

The

stage II T3 has

an

exducer diameter of

2.122" and a

major diameter of

2.559"

The

stage III T3 has

an

exducer diameter of

2.229" and a

major diameter of

2.559"

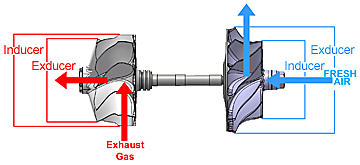

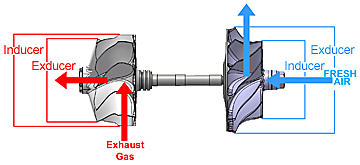

Trim is a ratio of the minor (inducer) diameter compared to the major (exducer)

diameter of the compressor wheel as calculated below.

360 degree bearing means the thrust bearing is a complete circle, not cut out

in one section like the 270 degree bearing. Obviously a full bearing will

provide more thrust support than a partial bearing which makes a 360 bearing

better for performance applications.

Adiabatic Efficiency of a Compressor: The ratio of the work input required to

raise the pressure of a gas to a specified pressure as related to the actual

work input. Basically it shows how efficient the compressor wheel design is at

pressurizing the air to a certain pressure/ how well it can pump air without

heating the air more than thermodynamic law says it should.

How much boost can my turbo put out before it becomes overly inefficient?

-IHI~18psi

-T3~23psi

-50

Trim~35psi

-57

Trim~27psi

-Holset~35+psi How

much boost can I safely run on 91 octane?

These are general

guidelines only. Always test with windows up, muffled exhaust, radio off, etc.

so you can listen for audible detonation. Detonation sounds like gravel

rattling in a tin can down near the back of the engine/transmission

bellhousing. If detonation is

heard, get out of the throttle immediately and lower boost or timing until it goes away.

Since there are so many factors that effect this, I'll try to cover as many as

I can but keep in mind that every vehicle is different and many other factors

besides those mentioned below will effect maximum allowable boost. Please do

not just crank the boost to the top of the range listed below and assume

it will be OK as this almost always results in a blown headgasket or

melted pistons. The lower side of the range would be for 91 octane, the

higher side would be 93 octane.

-Assuming no intercooler, stock timing with an early (not LA or PE series) ECU,

premium fuel.

12-16psi.

-Assuming stock intercooler, stock timing with an LA or PE series ECU,

premium fuel.

16-20psi.

-Assuming large efficient front mount intercooler, stock

or slightly turned down timing with an LA or

PE series ECU, premium fuel.

19-23psi.

Other

factors to consider:

-93 octane should allow additional

2-3psi over 91 octane, 89 octane will lower max boost 3-6psi, 87 octane will lower max

7-10psi.

-Small or inefficient intercooler (Volvo, Saab, Probe, etc.) should lower max

boost 3-5psi.

-Cold air temps may raise max boost 2-3psi.

-Hot air temps may lower max boost 2-4psi.

-Water/Alcohol injection can raise max boost 2-10psi.

-Larger than stock turbos may raise max boost

1-3psi because of increased

compressor efficiency.

How much power will the stock LA series ECU handle?

In general terms,

about 250-275 rwhp. This will require elevated base fuel pressure, elevated boost,

and other airflow mods before this power can be achieved though.

Early ECU's running 30lb injectors or small air meters will support

significantly less power, somewhere closer to 235 rwhp.

How much power will the stock 35lb injectors handle?

In general terms

with stock fuel pressure, about 230-250 rwhp, though you can push them to ~275

rwhp

if using elevated base fuel pressure.

How much power will the stock large vane air meter (VAM) handle?

In general terms,

about 275 rwhp. It's actually quite a restriction at anything over about

215 rwhp and people have pushed them to over 300rwhp, though they are no

longer reading additional airflow over about 215 rwhp and it's like

sucking a cheeseburger through a straw at this point. The easiest way to

remove this restriction and allow the use of larger injectors and full tuneability is our

PiMP ECU's.

How much power will the stock turbo engine handle?

With stock crank, rods, pistons, etc., many people have safely ran them in

the 400-415rwhp range for quite a long time. A few people have made

515-550rwhp for a few wide open pulls before throwing a rod.

Can I convert my air meter to blow-thru?

Yes, it is

possible, though I wouldn't suggest it without a means of monitoring the

Air/Fuel ratio with a Wideband Oxygen Sensor such as one's we sell:

Widebands

Can I use a n/a head on a turbo motor?

Yes, you can, though I'd suggest you

port the chambers to remove most of the "heart" shape so it more closely

resembles the stock turbo head's "D" shaped chamber. You will also need

to upgrade the exhaust valves and install hardened exhaust seats.

Can I just put forged pistons in my stock 2.3 n/a engine and convert to turbo?

Yes, though I'd suggest you still do the

swap as if you were dropping in a complete 2.3 Turbo engine as far as

wiring, air meter, injectors, etc. go, or skip the wiring modifications

and air meter stuff involved with the stock ECU and go straight to one

of our

PiMP ECU's.

What spark plugs should I use?

Stock replacement Motorcraft,

Autolite, or NGK plugs

for 2.3T engine. Copper only, absolutely no platinum plugs or plugs with

multiple electrodes.

What the max spark plug gap I should run?

In general, too tight of a gap won't

really hurt anything but too large of a gap will allow the spark to blow

out so it's fine to run .024" for 15psi for example. New spark plugs

will need to be gapped as they come out of the box gapped WAY too large.

Max gaps for different boost pressures are listed below:

-.032"-(10-15psi).

-.030"-(16-20psi).

-.028"-(21-25psi).

-.024"-(25+ psi).

What spark plug wires should I use?

Motorcraft. Parts store brand

wires and many more expensive wire sets cause issues under boost. They

also include a lifetime warranty which can come in handy.

Can I use a small air

meter/injectors with a computer that came with large air meter/injectors (or

visa-versa)?

No. You must use

the same size air meter and injectors as came with the ECU from the

factory.

What options do I have

for tuning/modifying the stock computer settings?

-F3

Chip

(View Here) with Jaybird

(View Here) (Cheapest tuning option)

-Binary

Editor and EEC Analyzer Software

(View Here) (Tuning Software to be used with F3 or Quarterhorse)

-Quarterhorse

(View Here) (Tune and Datalog in real time)

The

F3

chip plugs into the stock ECU's service port and basically "interrupt"

the signal to the ecu.

They are tuned with a computer (laptop or pc). They are not tuned "on

the fly" meaning the engine is off during tuning. You can adjust

"anything" that the ecu controls, rev limiter, injectors,

timing, etc...anything you can dream of really.

The main difference between the J3 and the Quarterhorse is that the F3 uses

and external chip burner and can't tune with the engine running while the

Quarterhorse is self burned, meaning the

"burner" is part of the chip board and can datalog and tune in

real time (engine running) which is a huge benefit when tuning. The F3 uses removable chips

that can have different tunes burned onto them for easy swapping of tunes

without a computer (at the track or something).

What other EFI tuning

options do I have (Stand-Alone EFI)?

-Stinger

Performance PiMP

(View Here)

-Megasquirt

(View Here)

What is a wideband oxygen

sensor and why do I need one?

Air/Fuel Ratio

Primer: When air and

gasoline are mixed together and ignited, the chemical reaction requires a

certain amount of air to completely burn all of the fuel. The exact amount

is 14.7 lbs of air for every pound of fuel. This is called the "stoichiometric"

air/fuel ratio or 14.7:1 a/f. It's also referred to the Greek letter

"lambda."

Lean mixtures

improve fuel economy but also cause a sharp rise in oxides of nitrogen (NOX).

If the mixture goes too lean, it may not ignite at all causing "lean

misfire" and a huge increase in unburned hydrocarbon (HC)

emissions. This can cause rough idle, hard starting and stalling, and may

even damage the catalytic converter. Lean mixtures also increase the

risk of spark knock (detonation) when the engine is under load.

Rich mixtures:

When the air/fuel ratio is less than 14.7:1, lambda also is less than one

and the engine has a rich fuel mixture. A rich fuel mixture is necessary

when a cold engine is first started, and additional fuel is needed when

the engine is under load. But rich mixtures cause a sharp increase in

carbon monoxide (CO) emissions.

By monitoring the level

of unburned oxygen in the exhaust, the sensor(s) tell the engine computer

when the fuel mixture is lean (too much oxygen) or rich (too much fuel).

To compensate, the computer adjusts the fuel mixture by adding more fuel

when the mixture is lean, or using less fuel when it is rich. That's the

basic feedback fuel control loop in a nutshell.

Narrow Band

Sensors (Stock):

The stock oxygen sensor used on most vehicles is referred to as narrow

band. This is because it is designed to only be accurate over a very

narrow band of air/fuel ratios.

They are not useful for performance tuning. The reason is, conventional

oxygen sensors give only a rich-lean indication. They can't tell the

computer the exact air/fuel ratio. When the air/fuel ratio is perfectly

balanced, a convention O2 sensor produces a signal of about 0.45 volts

(450 millivolts). When the fuel mixture goes rich, even just a little bit,

the O2 sensor's voltage output shoots up quickly to its maximum output of

close to 0.9 volts. Conversely, when the fuel mixture goes lean, the

sensor's output voltage drops to 0.1 volts. Every

time the oxygen sensor's output jumps or drops, the engine computer

responds by decreasing or increasing the amount of fuel that is delivered.

This rapid flip-flopping back and forth allows the feedback fuel control

system to maintain a more-or-less balanced mixture, on average.

Wideband Sensors:

The newest generation of oxygen sensors are being called

"wideband" lambda sensors or "air/fuel ratio sensors"

because that's exactly what they do. They provide a precise indication of

the exact air/fuel ratio, and over a much broader range of mixtures - all

the way from 0.7 lambda (11:1 air/fuel ratio) to straight air.

When the air/fuel mixture is perfectly balanced at 14.7:1 (the

stoichiometric ratio and lambda equals 2), the sensor produces no output

current. When the air/fuel mixture is rich, the sensor produces a

"negative" current that goes from zero to about 2.0 milliamps

when lambda is 0.7 and the air/fuel ratio is near 11:1. When

the air/fuel mixture is lean, the sensor produces a "positive"

current that goes from zero up to 1.5 milliamps as the mixture becomes

almost air.

Widebands and Performance

Tuning: Many

performance engine builders and tuners have discovered the benefits of

using the wideband oxygen sensor technology to monitor air/fuel ratios.

Being able to see the actual air/fuel ratio at any given instant in time

allows the fuel mixture to be fine-tuned and adjusted on the fly -

something which previously could only be done on a dynamometer using

expensive equipment.

The air/fuel ratio is

critical with high performance, turbocharged and supercharged engines to

make power and to keep the engine from leaning out at high rpm and boost

pressures. If the mixture leans out, it can send the engine into

self-destructing detonation. If it is too rich, it will lose substantial

power and create excess heat.

Target Air/Fuel Ratios:

Typically, naturally aspirated engines make best power in the 12-13.5:1

range under load. Turbo engines are typically safer in the 11.3-11.8:1

range under load. Each engine is different however and the best ratio for

your particular combo may not fall within these ranges. These engines

should still idle and cruise at near 14.7:1 a/f ratio for best fuel

efficiency and minimal emissions. Large cams will idle at richer ratios

typically in the 13's AFR range.

Our Widebands are listed here:

Widebands

What is the purpose of a blow off valve (BOV)?

The Blow-Off valve

(BOV) is a pressure relief device on the intake tract to prevent the

turbo's compressor from surging from the backed up pressure waves

caused by a suddenly closed throttle. BOV's do not control boost

levels. The BOV should be installed between the compressor discharge and

the throttle body. When the throttle is closed rapidly, the airflow is

quickly reduced, causing flow instability and pressure fluctuations.

Airflow bounces off the throttle plate and the pressure waves can reverse

direction. These rapidly cycling pressure fluctuations are the audible

evidence of surge. Surge can eventually lead to thrust bearing failure due

to the high loads associated with it. The BOV releases these pressure

waves into the atmosphere when the throttle is closed during shifts or deceleration, creating an audible "woosh".

Blow-Off valves use a combination of manifold pressure signal and spring

force to detect when the throttle is closed. When the throttle is closed

rapidly, the BOV vents boost in the intake tract to atmosphere to relieve

the pressure; helping to eliminate the phenomenon of surge. Engines with

air meters (VAM, MAF) require dual pistons BOV's.

Our BOV's are listed here:

Stinger BOV's

What is the purpose of a bypass valve (BPV)?

The Bypass valve (BPV) performs the same function as the BOV above. The

only difference is the air is recirculated back into the intake tract in

front of the turbo, not released to the atmosphere. The BPV recirculates

excess air when the throttle is closed during shifts or deceleration,

creating a muffled "woosh" sound.

Our BOV's are listed here:

Stinger BPV's

What is the purpose of a wastegate?

On the exhaust side,

a Wastegate provides us a means to control the boost pressure of the

engine. The vast majority of gasoline performance applications require a wastegate.

There are two configurations of wastegates, internal or external. Both

internal and external wastegates provide a means to bypass exhaust flow

from the turbine wheel. Bypassing this energy (e.g. exhaust flow) reduces

the power driving the turbine wheel to match the power required for a

given boost level (speeds up or slows down the turbo). Similar to the BOV,

the wastegate uses boost pressure and spring force to regulate the flow

bypassing the turbine.

Internal Wastegates

are built into the turbine housing and consist of a “flapper” valve,

crank arm, rod end, and pneumatic actuator. It is important to connect

this actuator only to boost pressure; i.e. it is not designed to handle

vacuum and as such should not be referenced to an intake manifold.

External Wastegates

are added to the exhaust plumbing on the exhaust manifold or header. The

advantage of external Wastegates is that the bypassed flow can be

reintroduced into the exhaust stream further downstream of the turbine.

This tends to improve the turbine’s performance. On racing applications,

this wastegated exhaust flow can be vented directly to atmosphere.

Should I use an internal or external wastegate?

In general,

street/strip vehicles with stock turbos or small hybrids in the middle of

their power range can use internal wastegates without issue. If trying to

run low boost (under 15psi) it's harder to control with an internal

gate. As the power

limit of the turbo is reached (bordering on being too small), and internal wastegate will become less reliable at controlling boost. If the exhaust

side of a turbo is being pushed near the limit, an external wastegate

should be used. Also in setups where an external wastegate will simplify

installation, or those getting over 350rwhp, and external gate should be

used.

Will 3" exhaust kill my low end power because it doesn't have enough

backpressure?

No. The turbo

creates more than enough backpressure for the engine. The best turbo

exhaust is the least restrictive possible. This includes large tubing,

mandrel bends (not crushed in the bends), and a straight through muffler

design.

What is the best size of intercooler tubing?

In general,

the best size is that which minimizes size changes throughout the system.

Considering stock 2.3T's have a 2" outlet at the turbo and a

2.5" inlet at the throttle body, using 2.5" tubing only requires

one size change; from 2" to 2.5" at the turbo outlet or

intercooler inlet. If a 65-70mm throttle body is used, 3" tubing from

the intercooler to throttle body can be used but realize that 2.5" tubing

will support around 600 hp so 3" shouldn't offer a

power increase over 2.5" tubing unless you are making 600+hp but the

larger air volume in the 3" tubing will slow down throttle response a

bit.

Will too large of an intercooler or too much tubing cause excess lag?

Simply put,

no. The amount of air contained in the tubing/intercooler compared to the

amount of air the engine ingests every second is very minimal. The

difference in lag between no IC tubing to a large FMIC will be hundredths

of a second. In other words, it's not noticeable. With that said, it can

slow down throttle response a bit, more so with stock ECU/VAM but the

gains greatly outweigh the slower response.

What clutch do I need for

"X" hp?

Clutch needs will vary greatly depending on driving style, vehicle weight

and usage, torque curve, and many other factors. These are just general

guidelines. Of course you can always run more clutch than you need...it's

better to have more than you need than not enough.

Up to ~250rwhp: Stock Turbo Clutch or Spec Stage 2.

250-300rwhp: Spec Stage 2.

300-350rwhp: Spec Stage 2 or Spec Stage 2+

350-450rwhp: Spec Stage 3 or 3+

400-475rwhp: Spec Stage 3+ or 4 or 5, (Consider upgrading to a 5.0 clutch package with our

adapter plate at this point as it becomes difficult to hold the power

with a 9" clutch at this hp level)

500+rwhp: Dual Disc (Expensive) or Upgrade to a 5.0 clutch package with

our adapter plate at this point as it becomes impossible to hold the

power with a 9" clutch at this hp level.

Our clutch offerings can be viewed here:

Stinger Clutches

Can I use the stock Mustang fuel pump with my new turbo engine?

If you leave the

engine stock with only a few basic mods...cone filter, slightly elevated

boost, etc. you can most likely get away with it because the stock Mustang

pump is the same size as the stock turbo pump. If you plan to make

250+rwhp, see below.

What fuel pump should I use for my modified 2.3T?

Walbro 255 liter/hour

High Pressure for 87-93 5.0 Mustangs. Early SVO's and such with inline

pump (not in-tank) must either convert to in-tank pump or get inline Walbro

255 lph HP pump. Our fuel pump offerings are listed here:

Stinger Fuel Pumps

Factory 2.3T Vehicle Information:

The following information came from the seemingly

abandoned FordTurbo.com, recovered from:

www.angelfire.com/wa3/fastest4d/faq.html to make sure the

information wasn't lost if the site was pulled down.

Numbers ?

What years were the Cougar XR-7 made?

84-86

What years were the Turbo Coupes made?

83-88

What years were the SVO made?

84-86

What years were the Merkur XR4TI made?

85-89

What years were the Mustang GT (2.3turbo) made?

83-84 Gt in convertible and hatchback only

79-81 The GT's were a carb turbo

What years were the Capri RS Turbo made?

83-84

79-82 Capri's were a carb turbo

Engine ?

What/where is the VAM meter?

The VAM is the Vane Air Meter, it is a pre mass air unit.

It is located on the pass. side under the air filter box.

Which cars have the big VAM and small VAM?

Small VAM's are found in:

85-89 Merkur

83-86 Turbo Coupe

84-86 XR-7 Cougar

83-84 Gt Turbo

83-84 Capri RS Turbo

Big VAM/s are found in:

-All SVO's

-87-88 Turbo Coupes

What/where is the TPS?

The TPS is the Throttle Position Sensor,

it is located on the throttle body and allows the computer to read

the position of the throttle and adjust accordingly.

What/where is the IAC?

The IAC Idle Air Control solenoid it is located on the throttle body

just above the TPS and helps control the idle.

What/where is the ACT?

The ACT is the Air Charge Temperature sensor and is located on 87-88 Turbo

Coupes (and 87+ non turbo 2.3's). It

measures the air temp coming into the intake after the turbo so the computer

can correctly alter the timing.

It is located in the lower intake manifold facing the firewall.

It is the lower of 2 sensors found in that area.

What/where is the Knock Sensor?

The Knock Sensor allows your computer to hear detonation in the engine

and retard the timing.

(4 square)It is located in the lower intake manifold facing the

firewall.

It is the lower of top sensors found in that area.

(4 in-line) is located in the lower intake manifold and points

at the fender.

This sensor is commonly unplugged as it to prevent unnecessary retarding

of the timing due to false detection of detonation.

What/where is the O2 sensor?

The Oxygen sensor is used to sense the amount of oxygen in the exhaust

gas and

signals the computer, which can reference the voltage signal to an

air/fuel ratio.

It is located on the elbow of the exhaust system which connect the turbo

to the down pipe.

What/where is the FPR?

The FPR is the Fuel pressure regulator.

It helps keep a constant pressure of fuel to the engine.

It is located between the upper and lower intake manifold at the end of

the fuel rail.

What/where is the BCS?

The BCS is just an electronically controlled solenoid.

If you look at the way it is set up with the "T" fitting,

it works the same as a bleeder valve. But instead of using an adjustable

valve

it has a specific sized hole in the "T" fitting that allows a specific

amount of air to escape away from the wastegate's pressure line.

The BCS either turns on to allow the air to escape away from the

wastegate's pressure.

Since this air is escaping then the more air is needed to reach the

actuator's "preset" 10 PSI spring rate to allow it to push open the

wastegate.

With the BCS off then all of the air pressure goes to the diaphragm and

as

soon as 10 PSI is reached the wastegate flapper is pushed open.

It is located on the passenger inner fender next

to the BAP.

What/where is the Wastegate?

The wastegate is just a valve that allows air to bypass the turbo's

exhaust turbine.

No air blowing on the turbine means no boost is made. It is controlled

by the diaphragm that I described above. It is just a flapper door that is

controlled

by a spring set for 10 PSI. All the turbo cars have diaphragms set for 10

PSI.

What/where is the BAP?

BAP is a derivative of MAP. It's actually the same sensor on the MAP is

referenced to manifold pressure and a BAP is referenced to atmosphere

(not connected to the engine). BAP is a barometric pressure sensor. In is a minor computer input

that allows the computer to make corrections of the fuel and timing

tables

for different altitudes. Air density is different at different

elevations.

Just like how you had to tune a carbureted car differently if you drove

it

into the mountains.

It is located on the passenger inner fender next to the BCS.

Where is the PCV?

The Pcv Valve in these cars is hidden behind the alternator in a 5/8" ID

hose that runs under the lower intake and then up to the Upper intake

right near the throttle body.

What/where is the EGR?

The EGR is the Exhaust gas re-circulation.

It allows gases from the exhaust to go back though the intake and get

re-burned.

It is pretty much an emissions thing. Although it does help with gas

mileage. It is attached to the throttle body near the TPS.

There is a tube that runs from the back of the exhaust manifold around

the back of the

engine and to the EGR.

What stock fuel injector is 35 lbs/hr?

The 35lb fuel injector is a low impedance fuel injector. The top of the

injector is brown.

It can be found in:

85.5-86 XR-7 Cougar

85.5-88 Turbo Coupe

85-89 Merkur

85.5-86 SVO

What stock fuel injector is 30 lbs/hr?

The 30lb fuel injector is a low impedance fuel injector. The top of the

injector is green.

It can be found in:

83-85 Turbo Coupe

early 85 Merkur

84-85 SVO

84-85 XR-7

83-84 Mustang GT Turbo

83-84 Capri RS Turbo

Intake manifolds, 4 in-line vs. 4 square?

The 4 in-line intake manifolds were found in pre 85.5 2.3. The runners

are in a line.

The 4 square intake manifolds are found after mid year 1985. This

version has more aftermarket support as far as porting, fuel rails, etc.

What car(s) have a Garrett T3 turbo?

**All Merkur XR4Ti's

**All SVO's

**All 83-86 Turbo Coupes

**All 84-86 XR7,2.3 Cougars

**All 83-84 GT Turbo

**All 83-84 Capri RS Turbo

What car(s) have an IHI turbo?

**All 87-88 Turbo Coupes

What cars have what size turbo housings?

83-84 GT Turbo .60 & .63 A/R

83-84 Capri RS Turbo .60 & .63 A/R

84-86 XR7 Coug .60 & .63 A/R

84-85 SVO .60 & .63 A/R

85.5-86 Svo .60 & .48 A/R

83-86 TC .60 & .63 A/R

87-88 TC IHI Turbo

Early 85 XR4TI .60 & .63 A/R

85.5-89 XR4TI .60 & .48 A/R

What is the diff between a Garrett and an AiResearch Turbo?

There is no difference. They are the same company.

Which 2.3T engines were factory intercooled?

84-86 SVO

87-88 Turbo Coupe

Which cars have an E3 or an E6 exhaust manifold?

E3 and E6 exhaust manifolds are defined by their production number E3

means

that is was produced in 83. E6 means it was produced in 86 so all turbo

manifolds post 86 are E6.

Trans ?

How do I know what trans I have?

83-84 GT Turbo ----T5

83-84 Capri RS Turbo----T5

84-86 Cougar XR-7 ----T5 or C3

84-86 SVO ----T5

83-86 TC ----T5 or C3

87-88 TC ----T5 or A4LD

85-89 XR4TI ----T9 or C3

How do I know if my T5 is a world class version?

All T5 transmissions after 86 are World Class.

Diff ?

What diff and gears does the Svo have?

The 84 SVO had a 3.45:1 final drive

The 85-86 SVO had a 3.73:1 final drive

All SVO Mustangs came with a 7.5 rear diff.

They all were 5-lug and were rear disc brake equipped.

What diff. and gears does the TC have?

83-86

3.45:1 final drive

83-86 TC were 4 lug with rear drum brakes.

87-88

The auto had a 3.73:1 final drive

The 5sp had a 3.55:1 final drive

All 87-88 TC came with the more stout 8.8 rear diff.

They all were 4 Lug and were rear disc brake equipped

What diff. and gears does the Merkur have?

5sp final drive is 3.64:1

Auto final drive is 3.36:1

They have an 7.5 diff. from the American produced 7.5. they have a 26

spline instead of a 28 spline.

What diff. and gears does the Mustang GT Turbo have?

3.45:1 final drive,

all had the 7.5 rear with 4 lug rear drum brakes.

What diff. and gears does the Cougar xr7 have?

3.45:1 final drive,

all had the 7.5 rear with 4 lug rear drum brakes.

What diff. and gears does the Capri RS Turbo have?

3.45:1 final drive,

all had the 7.5 rear with 4 lug rear drum brakes.

Electrical ?

What is an EEC-IV?

The EEC-IV is the Electronic Engine Control processor the 83-95 Ford vehicles are

equipped with. This is the pre OBD-2 standard.

Where is the EEC-IV computer located?

It is inside the vehicle and is located just behind the passenger kick

panel.

What are the different EEC-IV and what cars did

they come in?

84 Svo 5sp --- ZBA and TE

85 Svo 5sp --- TJ and PJ

85.5-86 Svo 5sp --- PE

83 TC 5sp --- PC1 and ZGA

84 TC 5sp --- PC1 and TF and TC

85-86 TC Auto --- PK1

85-86 TC 5sp --- PC1

87 TC 5sp --- LA and LA2

88 TC 5sp --- LA3

87-88 TC Auto --- LB2 and LB3

88 TC Auto --- 8UA

85 XR4TI Auto --- PK

85.5-89 XR4TI Auto --- PK

85-89 XR4TI 5sp --- PF2 and PF3

83-84 GT Turbo 5sp --- TA

83-84 Capri RS --- TA

84-86 XR7 5sp --- PC1 and TA

84-86 XR7 Auto --- PK1

If you have any questions or have suggestions for new FAQ's, feel free to

contact us

HERE

©

Stinger Performance Engineering 2020

|