|

91-93 Turbo Swap Wiring Info

Step-by-Step Engine Swap Instructions can be

found

HERE

91-93 Mustang Turbo Swap Instructions (Updated

June 2017)

by Igloo75 & Stinger

If you want a

printable checklist while you are doing the swap, left-click or

right-click/save-as here (note that printable version may not always be up

to date with what is below):

Turbo Swap Instructions

1. Intro

This

is specific to the 91-93 LX cars receiving the '87-88 TC computer and VAM

harness ONLY. If you insist on running a different ecu (83-86 TC, SVO,

Merkur, ect) then you'll have to modify the wiring accordingly. An 87-88

ECU is only $50-75 though and is a much more capable ecu so I suggest

you just purchase one of you don't have one. Be sure you also have a big

vam (3" in/out) and 35lb fuel injectors (brown tops) to go with it.

IF YOU DON'T WANT TO DO ANY WIRING

CHANGES BUT WANT TO RUN A TURBO ENGINE IN YOUR CAR: Our PiMPx ECU

is completely programmable and allows you to run your factory ignition

system/wiring with a turbo without doing any of the wiring changes listed

on this page.

If you want to

skip all of these instructions and not have to buy the old 35 year old

ECU, air meter, injectors, etc., all of which are limited to around

250hp anyway, while also upgrading to a modern and tunable ECU, you can

use our PiMPx ECU and use the DIS (distributor ignition system)

components on the turbo engine with the stock DIS harness. Our plug and

play ECU's are listed here:

Stinger ECU's

This

how-to only requires the use of a small portion of the Turbo Coupe

harness (the vam plug and the coil plug). You DO NOT need the entire TC

harness as you will be modifying the stock Mustang harness. We sell the

VAM pigtail (two versions) here:

Pigtails

These notes are for

a 5 speed car only, but should be close if you wanted to do an auto trans

conversion. (who would do that)?

I have noticed elsewhere that others have had problems with their airbag

systems and the IRCM wiring. With this wiring there is no problems with

that.

First off try to use as many pieces as possible from an 87-88 Turbo Coupe,

as it will simplify the conversion process. You do not need the whole

wiring harness from the t-bird, only a few connectors. you will need the

VAM harness connector, the knock sensor connector (I did not use a knock

sensor), and you will also need the coil connector.

DO NOT remove the harness from the Mustang.

You ARE NOT using the Turbo Coupe harness

in your Mustang. There are many wires for

sensors and modules in the Mustang harness that are not used with the

turbo engine, such as the MAF wires and the DIS ignition wiring.

Read this article carefully and you should be set on how to wire the

conversion. if you do not understand something feel free to study that

area until you do understand. If you do not you could end up messing up

something that could be costly to repair.

Also feel free to email me with any questions, or if you find any errors

in this article. I will not accept responsibility for anything you might

fry in the process of doing this swap. I advise researching all the wiring

diagrams and EEC4 info you can get your hands on.

2. Re-pinning the computer

I am not going to explain how to remove and install pins from a connector,

if you can't figure it out you might not want to do this swap. I

will give you a hint though, a small screwdriver or small razor knife

works well.

SEE CHART BELOW FOR PINOUTS!!!!

3.How to Connect VAM Wiring

To do this part find the MAF connector and cut it off about an inch from

the connector (4 wires). Now splice in 3 of the wires from the VAM pigtail

to the MAF wires with arrows next to them as follows: (soldering recommended)

|

MAF wires

|

VAF wires |

|

lt blue/rd----> |

lt green/purple |

|

tan/lt blue----> |

white/black or

yellow |

|

orange/white

(or red) |

orange to brown/white

@ BARO (see note 1 below) |

|

black----> |

black (or

black/white)

|

Now at the computer

move the lt blue/red wire from pin#14 to pin #43

next at the computer move tan/lt blue wire from pin#15 to pin #27

(Both of these steps are mentioned again when doing the rest of the ecu

repinning)

note 1: For the 4th

VAM wire, you need to run a wire from this to the brown/white

wire at the BAP sensor. This is a 5v reference. Don't cut the wire at the

BAP, just "T" into it so the final wiring goes to the BAP and VAM.

Both the VAM and BAP should have 5v from this wire when wired correctly.

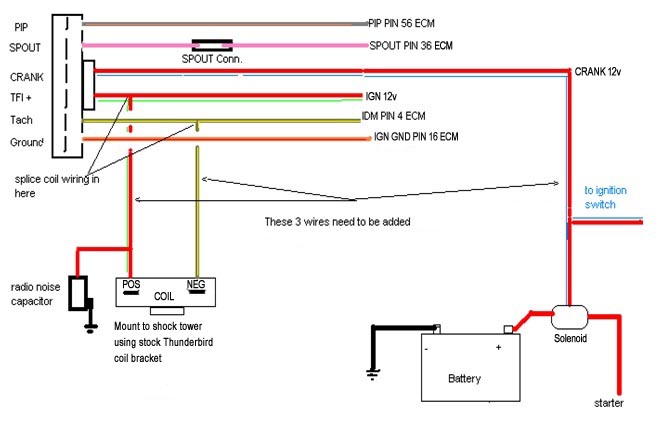

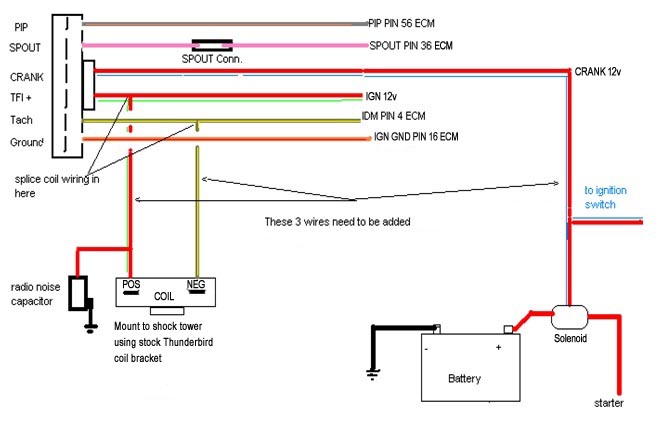

4. Wiring the ignition

The original harness section of the N/A engine is removable from the main

portion of the wiring harness. I recommend laying it out on the bench to

do this project as this is the worst of the wiring. There may be some

questions about this part of the wiring as far as routing of a few of the

wires you will need to figure out on your own. I will show you where to

connect them.

Once you get the harness section out take all the wire loom and tape off

the whole section of harness.

Find the two connectors that originally went to the DIS module (one is

black, one is grey)

Now take the TFI ignition module connector from the T-bird wiring and use this

as a wiring reference to get the order of the wires correct, as you will

be repinning the grey DIS Mustang ignition module connector to match the

TFI wiring harness of the turbo motor. This grey connector will plug into

the TFI module after the wiring changes.

Wiring from the top of the t-bird connector:

dark blue ---------->(PIP)

yellow/light green--->(SPOUT)

red/light blue------->(crank signal)

red/light green------>(12V ignition)

white/light blue----->(tach, IDM)

black/orange------->(ground)

Now, for reference, the DIS connectors "should" be wired like

this in stock form (the colors vary a bit year to year)If the colors don't

match, it's ok. The wire LOCATION is what is important, not the colors.

If the colors don't match, I'd suggest you write down what your colors

are in each position so you can create two wire color columns and number

them by position like below:

Grey connector from top:

Black connector from top:

1-orange/red (foil

wrapped)

7-blue/yellow

2-tan/blue

8-tan (or pink)

3-tan/green

9-blue

4-tan/orange

10-grey/orange

5-tan/white

11-red/light blue (or blue/tan)

6-tan/yellow

12-red/light green

Now you need to remove the pins from both

of the DIS connectors above and replace

them in different positions into the grey connector as follows. Again, if

the colors don't match, it's ok, it's the wire position from the

original Grey and Black connectors above that matter:

From top of connector:

10-grey/orange----->(PIP)

8-tan (or pink)------>(SPOUT)

11-red/light blue (or blue/tan)-->(CRANK 12v) this

wire needs to be run to the location of the small wire on the top of the starter solenoid,

just put a small ring terminal on the end of it and slide it onto the

small post on the solenoid. So the final configuration has this wire going

from the TFI connector to the small post on the starter solenoid near

the coil on the inner fender.

12-red/light green-->(IGNITION 12v)

this wire needs to go from TFI connector to the positive

side of coil (White)

6-tan/yellow------>(COIL NEGATIVE)

this wire needs to go from TFI connector to the negative side of coil (Green)

1-orange/red------>(IGNITION GROUND)

When I did this there is extra wires such as the crank sensor and (leftovers) from

the DIS wiring. You can remove the cranks sensor wires and the extra DIS

wires. The extra DIS wires could be used for knock sensor wiring if moved

to the correct pins at the computer. I opted not to use a knock sensor so

I cannot get into details here. You should be able to eliminate

about 6-7 plugs when it's all said and done. When removing the old

coil pack plugs, be sure to connect all of the leftover red/green signal

return wires

together or you may end up with a no-spark condition and no power to the

engine sensors (tps, vaf, bap, etc).

Here is a wiring diagram for the ignition system:

When you are done wiring this little section wrap the harness up with new

loom, and tape it up nice.

Note here I used the throttle body from the

91-93 engine to keep from having

to change any TPS wires. If you want to use the T-bird throttle body you

will have to change the connector. They are both the same size.

If you choose to use the turbo throttle body (one advantage is it has an

adjustable Throttle Position Sensor), here is what I've found as far as

wiring goes:

Turbo

TPS Plug/Stock 1991 Plug

From Top:

Orange------->Brown/White

Green-------->Grey/White

Red---------->Grey/Red

Be sure to mount the coil behind the battery with the factory mount from

the thunderbird.

Be sure

to remove the vacuum line from the factory 91-93 Mustang MAP sensor. This

makes it a BAP sensor which is what the turbo engine needs to run

properly. This sensor is what you ran orange/white VAM wire to at the

beginning of this article.

The Mustang oxygen sensor

can be used with the TC computer if you swap it into the turbo down elbow

where the factory sensor on the turbo engine resides. The turbo ECU is

set up for a 3 wire o2 sensor and the Mustang uses a 4 wire unit with

integral HEGO ground wire (hence the difference between the 3 wire 87-88

TC o2 sensor and the 4 wire Mustang o2 sensor). The Turbo Coupe has an

orange external ground wire that bolts to the turbo. If you want to run

the 87-88 TC o2 sensor, one of the alignment tabs will need to be removed

to get it to plug in. The 3 wires are in the proper locations, just make

sure you follow the instructions for pin 49 in the pinouts listing below

to account for the 4th o2 wire.

You will need to use the

fuel injector harness from the Mustang so you can plug it into the stock

harness. All the wires are correct. Make sure you don't use

the 91-93 Mustang injectors or fuel rail, they won't work.

Note that you will need

to move that ACT Sensor that was located in your airbox to somewhere after

the intercooler. The 87-88 intakes already have them in the back of

the lower intake. You will need to move/lengthen the wires to reach

the new location. I chose to mount mine in the IC tubing right

before the throttle body. If you're running a PiMP ECU or other

aftermarket ECU, it is best to mount the ACT in a location that's less

likely to heat soak when the engine is idling, or has been shut off

while hot. This would mean the upper intake is a better location than

the factory lower intake location, and in the intercooler tubing after

it leaves the intercooler but before it gets near the engine would be

ideal. This way the sensor outputs accurate air temp readings under all

conditions.

Also note I did not use the coolant temp sensor that is located in the

t-bird intake manifold, I kept it in the location it is in originally in

the Mustang (in the heater hose). You will need to do this as well to get the fan to function.

If

your base turbo engine is a 83-86 model you will need to rig up your own

fuel lines from the rail to the steel lines located near the bell housing.

The stock mustang ones will not work. The 87-88 cars hook right up

to the stock lines. I chose to cut the lines out of the turbo coupe

and then cut them to the length needed for the mustang. I then slid

the factory style connectors into the plastic fuel line (may need to

smooth out ends of connections with grinder and then lube to get them

inserted all the way) and then used two small hose clamps on each one to

keep them from leaking. If was the cheapest/quickest way I could find to fix

the problem.

Plastic fuel line repair kits are available from most parts stores that

allow you to make the lines just like they came from the factory without

using hose clamps. This is the best option.

If you want to have a functioning octane switch (a toggle switch that

modifies the timing map for premium and regular fuel), you'll need to

install a toggle switch and wire it so it grounds pin 24 to put it in

premium mode and removes the ground for regular mode.

Here

are the pinouts for the computer swap:

|

Pin 1 KAPWR

|

yellow

|

OK |

|

Pin

2 BOO

|

lt grn

|

OK |

|

Pin 3 VSS DIF+

|

gry/blk

|

OK |

|

Pin 4 IDM

|

tan/yel

|

OK |

|

Pin

5 CID

|

dk blu/or

|

Remove pin |

|

Pin 6 VSS DIF-

|

pnk/or

|

OK

|

|

Pin 7 ECT

|

lt grn/rd

|

OK |

|

Pin

8 FPM

|

dk grn/yel

|

Remove pin |

|

Pin

9 DATA-

|

pnk/lt blu

|

Remove pin |

|

Pin 10 ACCS

|

blk/yel

|

OK |

|

Pin

11

|

OK |

|

|

Pin

12

|

OK |

|

|

Pin

13

|

OK |

|

|

Pin 14 MAF

|

lt blu/rd

|

Remove pin and

install @pin 43 (Note 1) |

|

Pin 15 MAF RTN |

tan/lt blu

|

Remove pin and

install @pin 27 (Note 2) |

|

Pin 16 ign gnd

|

or/rd

|

OK |

|

Pin 17 STO/MIL

|

pink/lt grn

|

OK |

|

Pin

18

|

OK |

|

|

Pin

19

|

OK |

|

|

Pin 20 CASE GND

|

blk

|

OK |

|

Pin 21 ISC/BPA

|

wht/lt blu

|

OK |

|

Pin

22 FP

|

lt blu/or

|

OK |

|

Pin

23

|

pin in Knock Sensor

here |

(Optional) Only necessary if knock

sensor will be used |

|

Pin 24 PSPS

|

yel/lt grn

|

Cut wire and ground it to the chassis for premium

fuel only mode or ground this wire with a toggle switch for premium/regular

fuel switching manually. When grounded 91+ octane fuel is required. |

|

Pin

25 ACT

|

gry

|

OK |

|

Pin

26 5VREF

|

brn/wh

|

OK |

|

Pin 27 EVP

|

brn/lt grn

|

Remove pin

replace with pin moved from pin 15 (Note 2) |

|

Pin

28 DATA+

|

tan/or

|

Remove pin |

|

Pin 29 HEGO

|

gry/lt blu

|

OK |

|

Pin 30 NDS

|

lt blu/yel

|

OK |

|

Pin 31 CANP

|

gry/yel

|

Remove pin splice

in BCS if used (I use manual boost control instead) |

|

Pin

32 DPI

|

dk blu/yel

|

Remove pin |

|

Pin

33 EVR

|

brn/pnk

|

OK |

|

Pin

34

|

OK |

|

|

Pin

35

|

OK |

|

|

Pin

36 SPOUT

|

pnk |

OK |

|

Pin

37 12VPWR

|

red

|

OK |

|

Pin

38

|

OK |

|

|

Pin

39

|

OK |

|

|

Pin 40 PWR GND

|

blk

|

OK |

|

Pin

41

|

OK |

|

|

Pin

42

|

OK |

|

|

Pin

43

|

Install pin 14 here |

Install pin 14 here

(Note 1) |

|

Pin 44 OCT ADJ |

dk grn

|

Remove pin |

|

Pin

45 BP

|

lt grn/bk

|

OK |

|

Pin 46 SIG RTN

|

gry/rd

|

OK |

|

Pin 47 TP

|

gry/wh

|

OK |

|

Pin 48 STI

|

wht/ppl

|

OK |

|

Pin 49 HEGO

GND |

orange |

OK if running 4

wire o2 sensor, splice into

wire and run to turbo hot side for o2 sensor ground if running 3 wire

o2. |

|

Pin

50

|

OK |

|

|

Pin 51 EDF

|

lt grn/ppl

|

Move this to pin

55 for cooling fan function. (I opted to use only one speed cooling

fan) |

|

Pin

52 SS 3/4

|

org/yel

|

Remove pin |

|

Pin 53 CCO

|

ppl/yel

|

Remove pin |

|

Pin 54 WAC

|

pnk/yel

|

OK |

|

Pin

55

|

empty

|

|

|

Pin

56 PIP

|

gry/org

|

OK |

|

Pin

57 12VPWR

|

red

|

OK |

|

Pin 58 inj bank1

|

tan

|

OK |

|

Pin 59 inj bank2

|

wht

|

OK |

|

Pin 60 PWR GND

|

blk

|

OK |

© Stinger Performance Engineering 2020 |