|

|

Tech Articles

Contents

TPS Adjustment

IAC

Cleaning & Adjustment

Base Idle Reset

Timing Belt Replacement

Timing Adjustment

Timing Adjustment/Reset

w/o Timing Cover

Manual Cooling Fan Switch

Wiring

91-93 Oil Pan Removal

79-90 Oil Pan Removal

A/F Gauge Install

VAM Testing Procedure

Future Articles

Throttle Position Sensor (TPS)

Adjustment

Symptoms: high idle, won't idle, dies when throttle is lifted when slowing

down

These

sensors show as no longer available at most parts stores but if you

choose the right application, you can still get them from us here:

2.3 Turbo Adjustable TPS

1. First bring the

engine up to normal operating temperature.

2. Turn the

engine off and unplug the Idle Air Control (IAC). This is located on the

backside of the Throttle Body near the firewall. This device is a round

cylinder approximately 5 inches long with a (2) bolt flange and 3 wire

male / female plug connector (see pic).

3. Start engine

and using a screwdriver adjust the base idle to 700 – 800 RPM using the

screw on the throttle body (see pic)

4. Locate the

Throttle Position Sensor (TPS) on the Throttle Body. This is also located

on the backside of the Throttle Body near the firewall. This is a black

plastic device with (2) screws that allows adjustment and (3) wire male /

female connector (see pic above). Connect the voltmeter to the TPS and

ground. The wire should be either black with a green stripe or green with

a black stripe.

5. Using the

small Phillips screwdriver adjust the TPS output voltage to approximately

1.0 volts. Most turbo tuners find that setting your voltage to around .90

- .95 volts works best. I set mine around .94 volts.

6. Turn off the

engine.

7. With the

engine off and the voltmeter still connected move the throttle linkage

slowly from idle position to wide open and back to idle, look for a steady

increase and then decrease in voltage without any voids or dead spots. Any

voids or dead spots would indicate a faulty TPS. If you find a dead

spot you need to replace the TPS.

8. Plug in the

IAC.

9. Start the

engine. The engine’s idle speed should settle in around 1000 RPM. If

it settles higher than this, adjust the screw until idle is at 1000 RPM.

10. Go for a

test drive and enjoy the smooth idle.

Idle Air Sensor (IAC)

Cleaning & Adjustment

Symptoms: wandering idle, hanging high idle, idle problems when at operating

temperature.

Note: This is normally done in conjunction with the TPS adjustment above

to get the idle set properly.

1. Bring

engine up to operating temperature. This is located on the backside

of the Throttle Body near the firewall. This device is a round cylinder

approximately 5 inches long with a (2) bolt flange and 3 wire male /

female plug connector (see pic above).

2.

Turn the engine off

and unplug the Idle Air Control.

3. Remove 2 screws near the plug.

4. Remove two bolts holding the

cylinder on the throttle body.

5. Push "piston" inside canister in and out to see if it moves freely.

6. Spray carb cleaner into piston area and move piston to clear out carbon

deposits, repeat.

7. Blow out the excess cleaner and carbon deposits with compressed air

(your mouth will suffice if it must)

8. Install

cylinder with bolts.

9. Install plug with screws.

10. Start car, if it won't stay running then turn the idle adjustment

screw on the throttle body towards the driver's side until it will stay

running.

11. Turn the idle screw until it reaches 600-700rpm at idle.

12. Plug in

3 wire connector, if the IAC is functioning the engine should

smooth out and the idle should jump up to 1000-1500 RPM.

13. Turn the idle screw until it idles at 1000rpm. Rev engine a few

times to be sure it stays at 1000rpm at idle.

14. Remove tools, shut hood, and go for a drive.

Base Idle Reset

1.

Bring car up to operating temperature.

2. Unplug the

IAC.

3. With the IAC

disconnected and the idle adjusted to 750 RPM, shut off the engine and

plug the IAC back in.

4. Unplug the

battery cable and let it sit for 30 minutes.

5. Hook the

battery back up and start the engine.

6. Let the car

idle for 10 minutes and then go for a drive. It may take up to 75

miles for the computer to fully reset and learn the new settings.

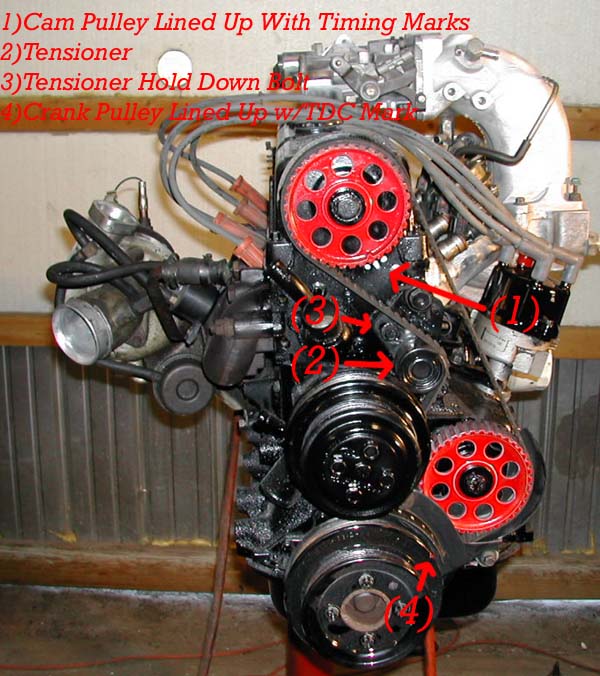

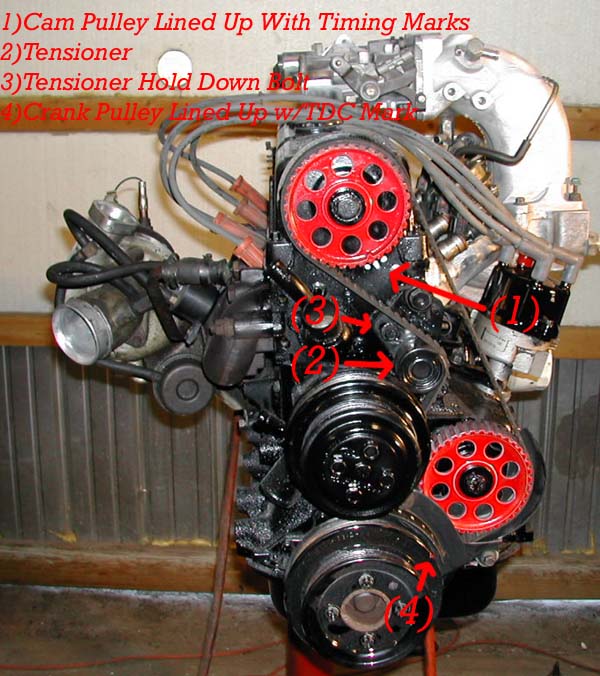

Timing Belt Replacement

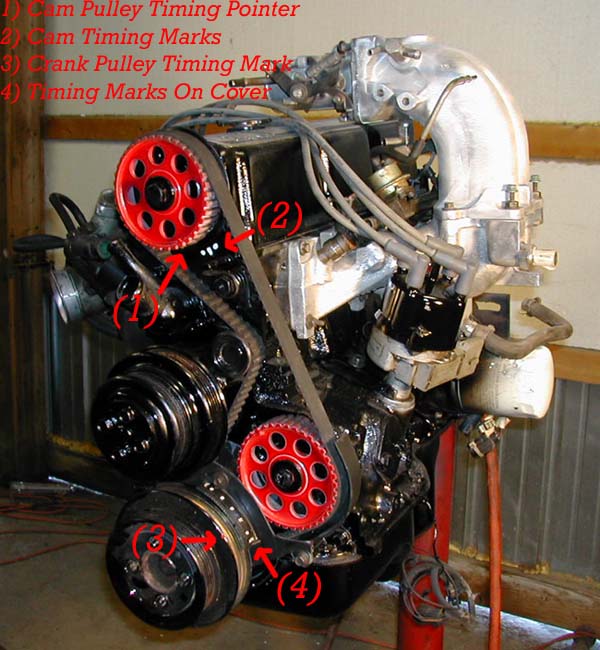

Use the pics below to

reference what is stated here.

Removing the belt:

1.

Set the engine at Top

Dead Center (TDC) on compression stroke (crank pulley mark should be at TC

on the timing cover and the cam notch should be visible through the little

hole in the timing cover, see pic below).

2.

Remove the timing

belt cover. This involves removes anything in its way (pulleys, etc.).

This is a real pain to remove if it's not already broke. Take your

time and remove whatever seems to be holding it on.

3.

Mark the cam, crank,

and auxiliary pulleys "straight up" with some chalk or a marker. Make

sure that they stay "straight up" throughout this procedure. If they

get moved slightly, move them back.

4.

Find the tensioner

hold down bolt (see pic below) that's located next to the tensioner pulley

and loosen it enough to move the tensioner.

5.

Put a breaker bar between the tensioner and the crank pulley or between

the tensioner and water pump and push upwards to release tension on the

tensioner pulley. It takes a good bit of force to release the

pressure.

6.

Once you release the

pressure, hold the breaker bar and tighten the hold down bolt in it's new

"loose" location.

7.

Now you can remove

the belt. The easiest way is to just cut the belt and pull it out of

the way.

Installing

the new belt:

1. Wiggle

your belt back onto the pulleys. It may take some work to get it

around the crank timing belt pulley.

2.

Once the belt is

routed properly, remove all the tension from the DRIVER'S SIDE of the

belt. You want to get it as tight as possible on that side.

Make sure the belt teeth are lined up with the cam and crank pulley teeth

and all the slack is removed. You may have to VERY carefully move

the cam back a little bit to get the belt on, then move it back again to

tighten it all the way up. The tension on the other side doesn't

matter because the tensioner will take care of it when it's released.

3.

Check to make sure all marks you put on the pulleys are still positioned

"straight up".

4.

Release the tensioner

hold down bolt slightly and the tensioner will spring back into place.

5.

Put the breaker bar

back under the tensioner and hold enough pressure on it so there is

approximately 1/2" of slack in the belt on the driver's side.

6.

Once the correct

slack is obtained tighten the hold down bolt.

7.

At this point the

hard work is complete and you can now install everything in the reverse

order of how you removed it. Once that is complete, check to make

sure everything is correct and then start the car.

8.

Now you can proceed

to the Timing Adjustment below to set the timing to factory specs.

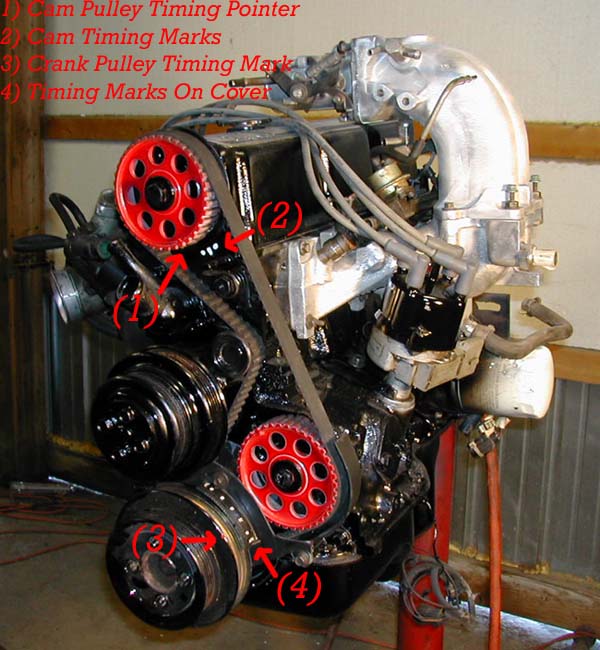

Timing Adjustment

Follow these steps after completing timing belt install above or to set

timing to factory specs.

1.

Make sure you have the

timing belt cover installed (or at least the lower part around the

crankshaft pulley)

2.

Put timing light connector on #1 spark plug wire (nearest the front of

the car).

3.

Locate distributor hold down bolt and use a 12+" long 3/8" extension

and ratchet to loosen bolt. You only need to turn it a small

amount...just enough to release the tension.

4.

Unplug spout connector (small gray plug located within 6" of ignition

module that's bolted to the side of the distributor, the plug is located

within the ignition harness).

5. Make sure the timing light wires are out of the way of the engine

pulleys.

6. Start car.

7.

Point timing light towards the timing marks near the crankshaft pulley

on the timing cover.

8.

Locate the 10* BTDC mark on

the cover (factory setting) and turn the distributor slightly until the

"notch" in the pulley lines up with the desired timing (10*BTDC).

9.

Once the desired timing marks are lined up tighten the distributor hold

down bolt.

10.

Recheck timing to make sure the distributor didn't move when

tightening it down.

11.

Plug in Spout Connector and check timing, it should be advanced to

20 degrees or more now and move with rpms.

12.

Shut off engine, remove tools, close hood, and enjoy your new found

power.

Timing Adjustment/Reset

Without Timing Cover

Follow these steps if you don't have a timing belt cover and have thrown

the timing belt.

1.

Turn over the auxiliary

pulley if you can't see the timing mark that is on it. Sometimes the

aux pulley is reversed so that you can't see the timing mark that is on

it. The aux pulley is the same part as the cam pulley but everyone

that I have seen is turned over so that you can't see the timing mark.

2.

Turn the crank so that the

crank bolt, the TDC mark (on the compression stroke, not the exhaust

stroke), the auxiliary pulley bolt and the auxiliary pulley

timing mark form a straight line. The crank and aux pulley timing mark's

will not be next to each other but both will be pointed in a straight line

with the crank and auxiliary bolts towards the driver's fender.

3.

If you can't or haven't

turned over the auxiliary pulley just check to see that the rotor button

is pointing to the Four O'clock position

4.

Check the distributor. The

rotor should be at about the 4 o'clock position, if not move it now.

The crank and auxillary pulley and distributor are now aligned.

5.

Now put a straightedge or piece of wire in a straight line between the cam

pulley bolt and the auxillary pulley bolt.

6.

Turn the cam until it's timing mark is in line with this straight line.

7.

You're done. If you

are stuck somewhere this method will set the timing to Zero Degrees BTDC.

This is an emergency method only. It will get you home however. Once

you get home, adjust timing to 10* BTDC as shown above.

Manual Cooling Fan Switch

Wiring

Reasons for doing this: Fan doesn't work, allowing manual control of fan

(useful for pulling air through the IC when getting ready to race)

Run a heavy (10-12 gauge)

wire from the positive side of the fan through the firewall and to the

location you choose to mount the switch. Attach it to the positive

(+) side of the switch. Leave the negative (-) wire on the fan in

its stock location. Run a black wire from the negative (-) side of

the switch to a screw on the fuse panel frame. Run a small wire from

the (acc) plug on the switch to a spot on the fuse panel that comes on

with the key at the accessory (acc) position or the on position and shuts

off when the key is off. Turn the key to (acc) and flip the switch

to (On). Make sure the fan is operating. Turn the key to (Ign)

and make sure the fan is operating again. Flip the fan switch to

(Off) and see that the fan quits. If it worked as described then you

are done. If not, start tracing your work to figure out what you

screwed up.

91-93 Oil Pan Removal

To remove the oil pan

"in-chassis", follow these steps:

1.

Raise the car and place it on jack stands.

2.

Drain the oil.

3.

Remove the motor-mount bolts

and raise the motor as high as you can with a winch. Support it

under the crank pulley with a stand and a block of wood.

4.

Disconnect the steering shaft from the rack and pinion at the "rag"

joint and tap it upward and out of the way (it's telescopic to prevent you

from being impaled).

5.

Take all 8 bolts out that attach the front crossmember to the "frame"

(it won't fall - trust me). The bolts have a torx head, but you can use a

standard 6-point socket.

6.

Remove the four bolts holding the anti-sway bar brackets to the frame

and let the bar hang.

7.

Drive a wooden wedge between the rear of the crossmember and one side

of the frame (this will not only lower it, as it compresses the suspension

springs which is what's holding it up, but it will usually slide forward

as well.

8.

Remove the starter.

9.

Drop the pan down low enough to disconnect the oil pump from the block,

allowing it to drop in the pan (you'll need an 8mm 12-pt socket for the

pump body and a 14mm for the pickup support.

10.

Slide the pan out the back.

79-90 Oil Pan Removal

To remove the oil pan

"in-chassis", follow these steps:

1.

Raise the car and place it on jack stands.

2.

Drain the oil.

3.

Remove the motor-mount bolts

and raise the motor as high as you can with a winch. Support it

under the crank pulley with a stand and a block of wood.

4.

Disconnect the steering shaft from the rack and pinion at the "rag"

joint and tap it upward and out of the way (it's telescopic to prevent you

from being impaled).

5.

Remove the four bolts

holding the anti-sway bar brackets to the frame and let the bar hang.

6.

Remove the starter.

7.

Drop the pan down low enough

to disconnect the oil pump from the block, allowing it to drop in the pan

(you'll need an 8mm 12-pt socket for the pump body and a 14mm for the

pickup support.

8.

Slide the pan out the back.

Compression Test

Be sure to bring the engine up to full operating temperature before

proceeding.

1.

First, take an air

compressor or shop vac and clean the area around each spark plug recess

BEFORE removing the plugs in order to prevent any dirt/sand from dropping

into the cylinder.

2.

If turbocharged, remove the intercooler. Be sure to cover the turbo inlet

hole with a towel or cup.

3.

Number each spark plug wire with clothes pins or tape and a pen so you can

return them to the proper location when reinstalling them.

4.

Remove the spark plug wires.

You should twist them while removing them to try to break them lose before

yanking on them. Try to pull on the rubber boots, not the wire

itself.

5.

Remove the spark plugs. Use the kind of compression gauge that screws into

the spark plug holes for best results.

6.

Install the Compression tester into the first spark plug hole and then

crank the engine over with the starter and allow enough time for the gauge

to hold at a given pressure (probably 4-6 compression strokes).

Repeat this process twice for each cylinder. Record the results for

each cylinder for comparison after completion.

7.

Ideal results would give you 120-150psi in each cylinder for a turbo motor

and 140-170 for a N/A engine. If your lowest psi is more than 20psi from

the highest psi (140 and 120 for example) then you have a problem.

8.

If you get a low reading on a cylinder, try adding about a tablespoon of

oil to each cylinder. If the readings go up significantly the second time

around, you know the rings are weak/bad. If the compression is low and

doesn't go up significantly in round 2, then compression is leaking past

the valves or the cam lobes are worn significantly. A lower compression

reading in one or two adjacent cylinders can be sign of a blown head

gasket.

9.

After you have tested all cylinders, reinstall the plugs and wires in the

proper order.

Air/Fuel Gauge Installation

Used to detect

lean/rich engine conditions.

1.

Disconnect negative (-) battery

cable.

2. Mount Gauge into whatever

location you have chosen (pillar, etc.).

3.

Wire gauge as follows:

Red Wire:

12v power source that is powered on/off with the key.

Black Wire: Ground to chassis.

Violet Wire:

Oxygen sensor signal wire. You can connect directly to the wire

coming off pin 29 on the computer in turbo applications (and many n/a).

Note: A/F Gauges are set up for N/A engines that run an ideal ratio of

14.7:1. If you are using it on a turbo motor you must remember that

the ideal ratio is 12.5:1. This means the ideal range when under

boost is 3-4 lights into the green lights (rich zone). When not

under boost it should be in the yellow (Stoich) range.

VAM Testing Procedure

Used to detect

faulty/out of adjustment VAM.

Testing for DC Voltage with your negative (-) lead on the signal return

wire and probing wires below with the positive lead:

VREF (orange) =

5.0-5.1v

VAT (light

green/purple) = ~2.8v @ 70*F

VAF

(white/black) = ~.25v @ 0%, 4.5v @ 100%, .8v-1.0v at warm idle (this

varies on idle speed)

You must also make sure that there are no dead spots (0 volts) when the

door sweeps from .25v to 4.5v. If this is the case then the VAM is

shot.

If you have any questions about any of these procedures feel free to

contact us

HERE

©

Stinger Performance Engineering 2020 |